Under the Green Deal, the EU has set ambitious targets for reducing greenhouse gas emissions and comprehensive climate and environmental protection. This framework aims to make the economy and the energy system more competitive, secure, and sustainable. As a vital sector of the economy, this also concerns microelectronics production on the way to a "Green Electronics Production" in Europe. The Green ICT Hub Resource-optimized electronics production, nine FMD locations, and their designated technology innovations contribute to this. The hub offers a broad technology spectrum with comprehensive offerings for semiconductor and PCB-based electronics production and facility equipment suppliers and materials and chemicals manufacturers.

Our services:

- Quantification of material, resource and energy consumption to optimize manufacturing processes in cleanrooms Analysis and consulting on energy efficiency of machines and systems, including CO2 accounting

- Characterization on test structures

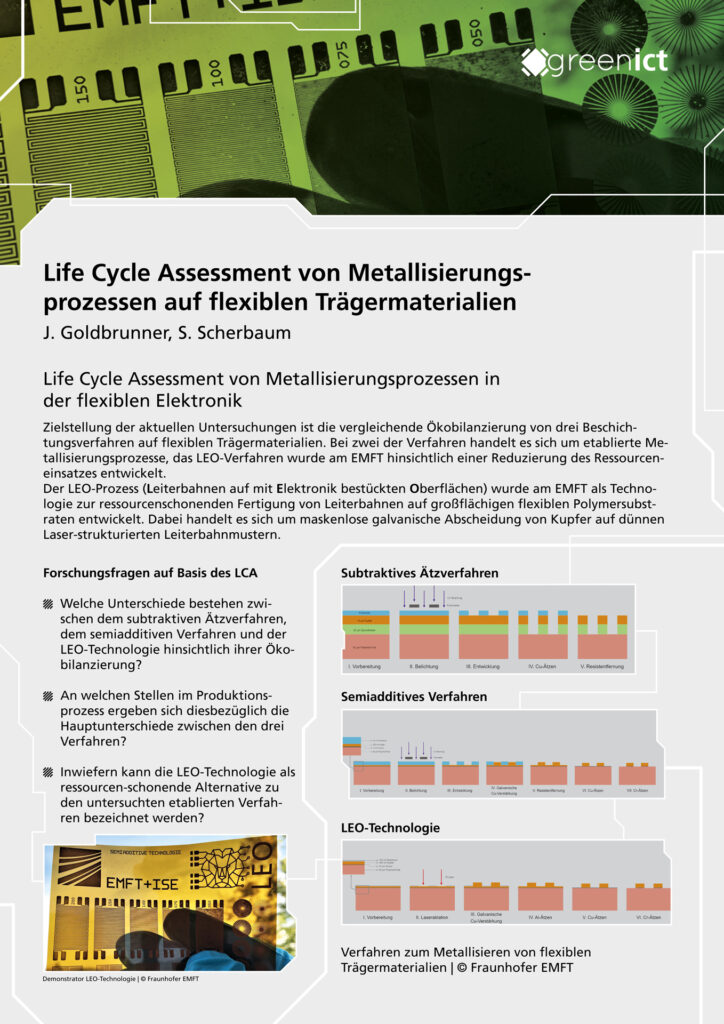

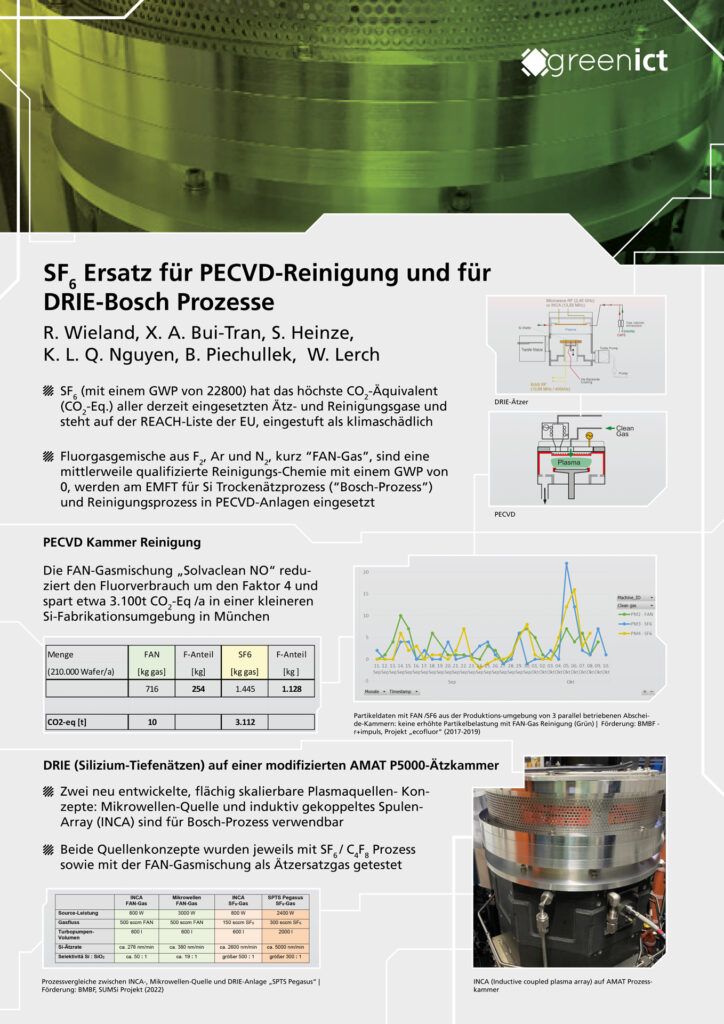

- Tests of alternative chemicals and processes (e.g. NMP, NF3, SF6…)

Video presentation of the hubs (only available in German)

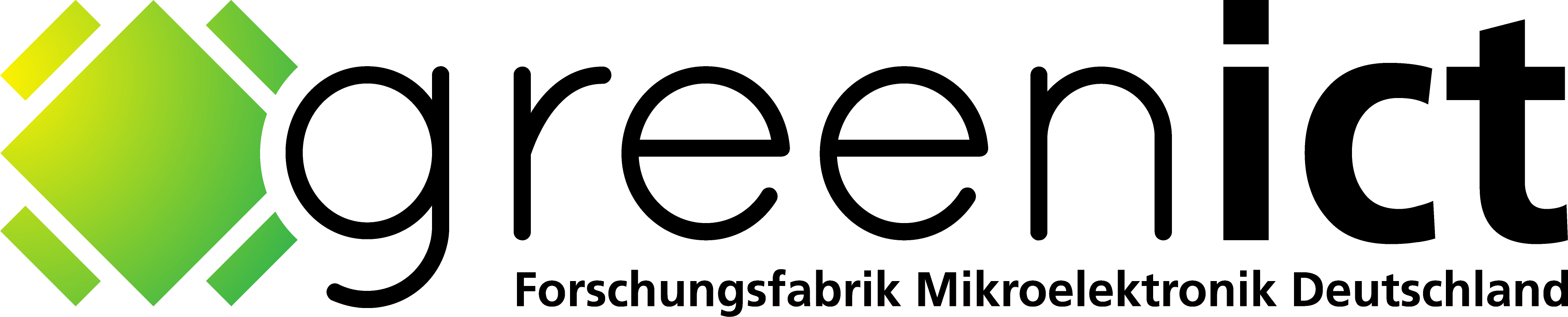

Info poster (only available in German)

Energy- and resource-intensive semiconductor production is particularly relevant to the environment. This includes the manufacture of raw wafers, the actual IC production, and the downstream assembly and interconnection technology at the wafer and panel level. All aspects of quality assurance are environmentally relevant here, as the best possible yield must be achieved to keep the carbon footprint low. In addition to the semiconductor industry, the printed circuit board and substrate industry, including components and assembly, will also become more critical from an environmental point of view in the future due to ever more highly integrated groups and increasing demands on reliability and durability. More and more processes require energy-intensive clean room environments and high-quality materials. Process yield reparability and recyclability are also green issues with ever-increasing importance for electronics manufacturing.

Insights into resource-optimized production practice in cleanrooms

A video by Fraunhofer IPMS, project partner of Green ICT @ FMD.

Work packages

- Hub coordination internally and externally (hub project management)

- Interface with FMD

-> Learn more about the validation projects