A project of muVaP GmbH.

Energy-efficient solutions for miniaturized applications

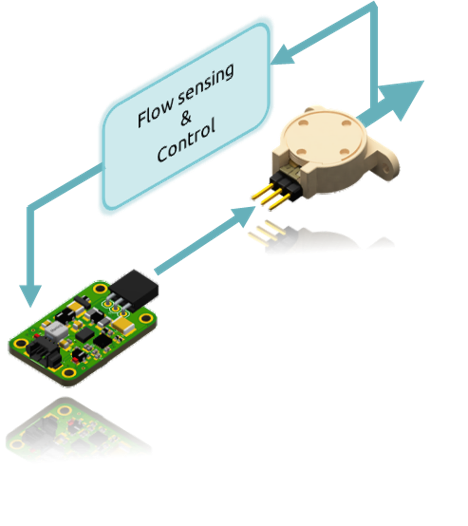

The aim of this project is to develop an application-specific integrated circuit (ASIC) for controlling piezoelectric actuators in the microvalves and micropumps manufactured by muVaP GmbH. This technology is significantly more energy-efficient than conventional solenoid valves. The more compact ASIC is intended to facilitate the transition from power-hungry solutions to highly efficient, energy-saving valves and ensure quieter, easier operation.

Currently, there are no efficient control electronics that enable the provision of miniaturized and energy-efficient devices. The valves from muVaP GmbH already demonstrate clear advantages, particularly in applications where the valves are used in a multi-array form, such as in dialysis machines. These valves offer improved energy efficiency and proportionality compared to conventional solenoid valves, which consume a lot of energy and generate unwanted waste heat.

Technical specifications and development process of ASIC

By the end of the project, functional chips are to be developed that can be tested in the valve's real working environment. To this end, the technical specifications, e.g., the requirements for the valve driver, such as voltage ranges and energy consumption, must first be defined. This will be followed by the development of a topology for the multi-channel high-voltage pump with energy recovery, followed by circuit board design, layout, and verification of the circuit. The ASICs will then be manufactured in the wafer fab, housed in a casing, and verified.

The prototype ASICs are then characterized together with the existing valves, measuring performance criteria such as power consumption and response time and comparing them with existing solutions. Safety tests, such as reverse polarity protection and overvoltage protection, are also carried out. The intended application of piezo micro-actuator technology ranges from biomedical and pharmaceutical fields to medical diagnostics and drug research.

Reduction of energy consumption and carbon footprint through innovative hardware designs

The size reduction of the control electronics significantly reduces the energy consumption of piezo valves; they typically require only about 40 mW compared to several watts consumed by solenoid valves. This energy saving contributes directly to CO2 reduction. In addition, improved hardware eco-design with fewer components and a more compact design enables more efficient use of the available space, which increases the efficiency of the application.

The project aims to reduce the number of components required for a valve actuator from over 50 to less than 10 by implementing an ASIC. This will result in a significant reduction in PCB space and thus also savings in weight, space, and costs.

Market opportunities and potential applications for microvalves in various industries

There have already been numerous inquiries from device manufacturers in the robotics, automotive, and medtech sectors who have recognized the immense application potential of microvalves. These valves are particularly attractive for pharmaceutical and medical technology because they offer a small footprint, extremely low energy consumption, and fast and precise response times. Examples of applications include control valves in medical ventilators, perfusion pumps for drug administration, and pneumatic valves in dialysis systems, cell cultures, and cell treatment devices. In addition, microvalves are also used in various industrial areas, such as inkjet printing, pressure control valves in aviation, satellites, and systems for controlling food and environmental quality. The introduction of the ASIC solution will significantly reduce production costs, creating great growth potential for muVaP GmbH.

After the project ends, Fraunhofer EMFT will focus on the industrial implementation and validation of the developed ASIC technology. The successful manufacture of ASIC samples and their testing are crucial to ensuring the reliability and functionality of the technology. In addition, the Fraunhofer Institute sees opportunities for further cooperation in the future to develop ASICs or other components for various applications, including micropumps and high-speed valves.

Project Partners:

Dr. Ardavan Shabanian, muVaP GmbH

Fraunhofer Institute for Electronic Microsystems and Solid State Technologies EMFT

Project period:

Start: 01.11.2024, End: 31.10.2025