Author:

Dr.-Ing. Stefan Zeltner

Group Leader On-Board Converter

Fraunhofer Institute for Integrated Systems and Device Technology IISB

The increasing use of AI has brought the power consumption of data centres, particularly high-performance data centres, back into the public discussion. This tech blog describes how the results obtained within the GreenICT project, aimed at the efficient power supply of CPUs and GPUs, can help keep the CO2footprint of AI as low as possible.

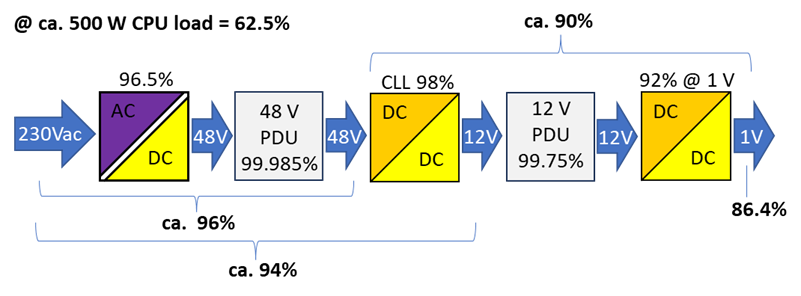

Due to the very low supply voltage of modern CPUs and GPUs, which is around 1 V, and their high-power demand of several hundred watts, it is necessary to employ so-called Point-of-Load (PoL) DC/DC converters to provide the low operating voltage directly "on-site", meaning right at the CPU or GPU. Otherwise, excessive losses would occur through the power delivery lines. In conventional high-performance data centres, CPUs and GPUs are installed within servers, which are then housed in racks. It has proven beneficial to supply all servers within the racks at a voltage level of approximately 48 V. This requires power supplies to step down 230 VAC to 48 VDC within the rack, and additional DC/DC converters within the servers to step down to 12 V and finally to around 1 V. Figure 1 illustrates the typical expected efficiencies of the individual stages in a block diagram.

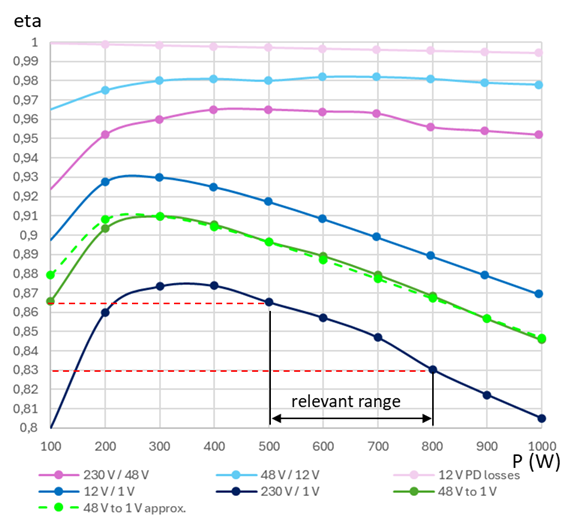

In this way, a total efficiency of approximately 86% can be expected. A closer look at the efficiency as a function of load power is shown in Figure 2. It illustrates that particularly the step from 48 V to 1 V, and more specifically the step from 12 V to 1 V, is lossy and load-dependent due to the associated high currents.

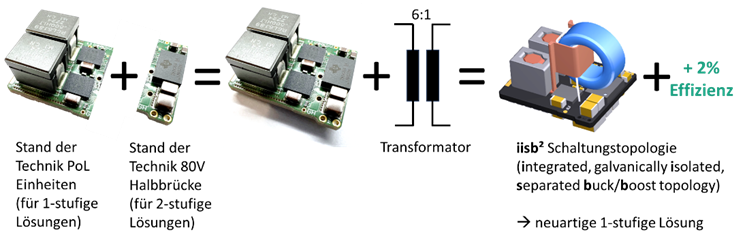

As part of GreenICT, an investigation was conducted on how a particularly efficient single-stage conversion from 48 V directly to 1 V can improve efficiency compared to conventional two-stage solutions. Figure 3 schematically illustrates the examined novel 48 V to 1 V PoL DC/DC converter, which can achieve up to a 2% higher efficiency compared to typical two-stage solutions.

The project also investigated how much CO2 equivalent could be saved in this manner and how much additional CO2 equivalent would need to be invested for this purpose. Table 1 presents the results:

Table 1: Potential CO2 equivalent savings in German data centres starting in 2030 for electric power generation scenarios ranging from 0.4 kg/kWh to 0.145 kg/kWh over an operating period of 10 years with 1.3%...2% increased 48 V / 1 V PoL efficiency

| CO2eqscenarios to produce 1 kWh electric energy in 2030 | 0,4 … 0,145 kg/kWh |

| CO2eq savings with 1.3% … 2% higher 48 V / 1 V PoL efficiency (260 GWh/a …320 GWh/a) | (104…128) … (38…46) kT |

| CO2eq savings within 10 years | (1040…1280) … (380 …460) kT |

| CO2eq additional: for 3.7 million 800 W servers with 1.3% … 2% higher efficiency | 19 kT |

| Netto CO2eq Einsparungen über 10 Jahre | (1021…1261) … (361…441) kT |

Even in future AI data centres, the PoL issue persists. Due to the use of direct liquid cooling, the power per server rack can be drastically increased, which necessitates an even higher voltage (e.g., 800 VDC) to supply the individual AI server units. This means that the challenge of directly converting 48 V to 1 V merely shifts from the rack/server level to the pure server level.

For additional information see:

[1] S. Zeltner et al.: IISB² Topology for 48 V / 1 V Point of Load Applications, PCIM 2025, Nuremberg, Germany [2] S. Zeltner et al.: Energy and CO2 Savings for High-Density Rack Servers Using 1-Stage and 2-Stage 48 V to 1 V PoL Solutions, MST-Kongress 2025, VDE, Duisburg